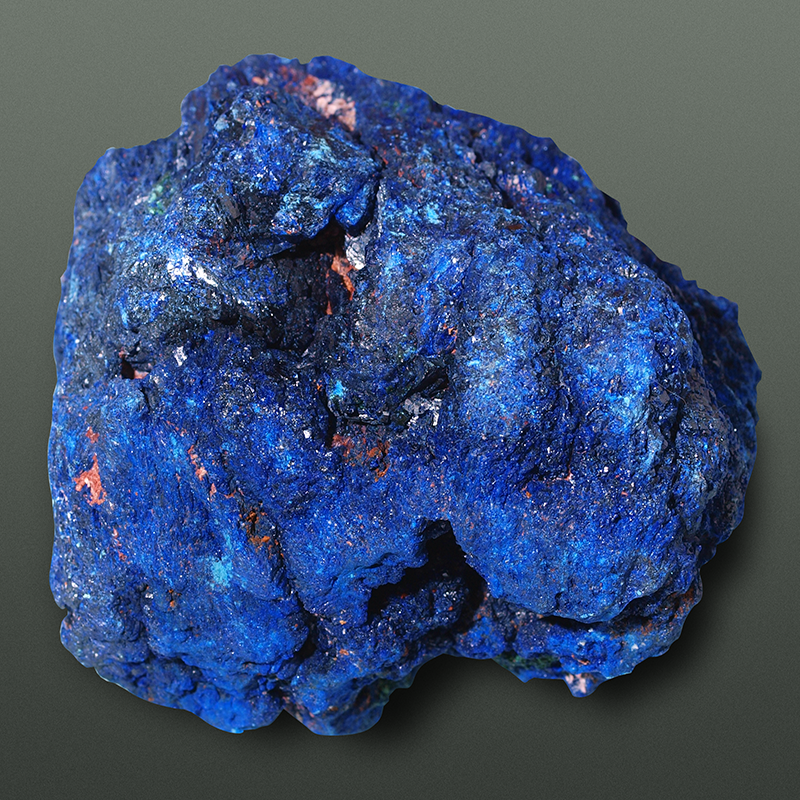

Azurite pigments

Azurite, Azurro della Magna (d'Allemagna), Mountain blue, Blue copper, Chessylite

Azurite, Azurro della Magna (d'Allemagna), Mountain blue, Blue copper, Chessylite

PB 30

Natural pigment suitable for icon painting (egg tempera), oil painting and watercolor painting without additional grinding.

Azurite is a natural basic copper carbonate, commonly found in the oxidized zones of copper ore deposits worldwide. This secondary copper mineral appears in over 40 forms of blue ore, including tubular prismatic crystals that form small, deep azure blue roses. Often found alongside malachite, azurite frequently pseudomorphs into this green mineral.

Historically, azurite has been used as a pigment since the Fourth Dynasty in Egypt. It was the most significant blue pigment in European painting from the fifteenth to the mid-seventeenth century, often more prevalent than natural ultramarine (lapis lazuli). Painters commonly used azurite in underpaintings due to its solid color and lower cost, reserving the more transparent and expensive natural ultramarine for glazes. The introduction of Prussian blue in the eighteenth century led to the decline of natural azurite in artists' palettes.

When properly prepared, azurite is one of the most permanent pigments known. Its reputation for morphing to green or darkening stems from the incorrect application of size as a binder, which fails to hold larger particles firmly and is prone to moisture, causing discoloration. Incorrect restoration techniques have also contributed to its bad reputation. Notably, azurite remains stable when mixed with lead white.

Our azurite minerals are sourced from the Jiangxi region in China, known for providing some of the best grades of this increasingly rare mineral. Finding high-quality azurite suitable for artistic use is challenging, but the Jiangxi mines continue to be a reliable source.

The preparation of azurite pigment begins with the careful hand selection and cleaning of raw geological specimens, often involving the manual grinding off of impurities. Given the wide variety of azurite forms and colors, the materials are sorted into different grades. Each grade is then resized into rough sand using a jaw crusher.

After washing the sand, it undergoes gradual milling in water using a high alumina ceramic ball mill with zirconia media, ensuring a virtually contamination-free process. Due to azurite's softness (3.5-4 on the Mohs scale), contamination during milling is negligible. The milling process produces a solution of water and pigment particles of various sizes, which are allowed to settle. At intervals of 10 to 30 minutes, the solution is decanted into different containers.

The settled pigment is repeatedly washed in water until the pH is neutralized. This is followed by an additional purification process unique to Master Pigments. The settled particles are mixed with a purification solution that binds impurities, turning the mixture grayish blue and causing a whitish sludge to float while clean pigment particles sink to the bottom. This process also slows sedimentation, aiding in the separation of the pigment into fine grades.

The resulting fine pigment, prepared by this method, is free of unstable particles, eliminating the need for further milling and producing exquisite shades of this unique blue color.