Lapis Lazuli pigments

Lapis Lazuli pigment (Lazurite, Natural Ultramarine, Azzurro Oltramarino, Fra Angelico blue pigment, Lapis Lazuli genuine, Ultramarine ash)

Lapis Lazuli pigment (Lazurite, Natural Ultramarine, Azzurro Oltramarino, Fra Angelico blue pigment, Lapis Lazuli genuine, Ultramarine ash)

PB 29

Natural pigment suitable for icon painting (egg tempera), oil painting and watercolor painting without additional grinding.

Cennino Cennini "Il Libro dell' Arte" - "Ultramarine blue is a color illustrious, beautiful, and most perfect, beyond all other colors; one could not say anything about it, or do anything with it, that its quality would not still surpass."

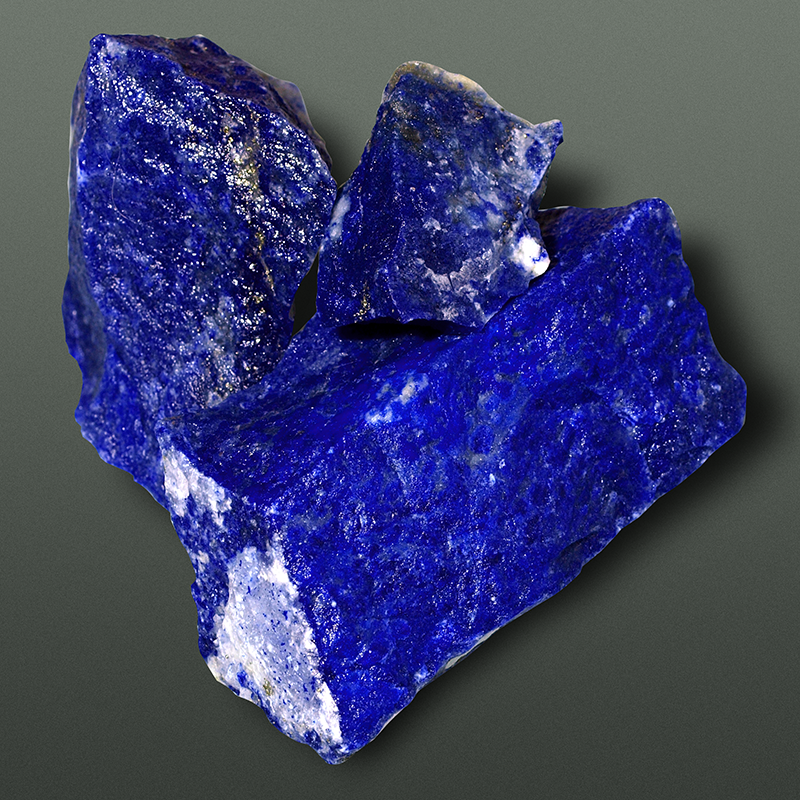

Lapis Lazuli is a blue semiprecious stone, historically mined in Afghanistan's Badakhshan province for centuries. While it can also be found in other parts of Asia and America, only a few Afghan mines produce the highest quality stones, known for their deep purplish-blue color. This complex mineral is composed of lazurite, calcite, sodalite, and pyrite. Its color varies from light blue denim to deep dark purplish blue, depending on the lazurite content. The highest-quality stones, often referred to as gem grade or AAA grade, feature a solid blue area with tiny veins of pyrite. Lower grades are more common and typically used for carvings. Some dealers enhance the color of lower-quality stones by dyeing them, and without standardized grading, these can be mislabeled as gem grade or AAA. Obtaining high-grade Lapis Lazuli often requires travel and careful personal selection.

Master Pigments prepares Lapis Lazuli pigments from these gem-grade stones. Years of research and experience have gone into understanding the various grades and sourcing the best rocks. The preparation process begins with cutting the raw stones into smaller pieces and removing as much calcite and pyrite as possible. These smaller pieces are then crushed into coarse sand using a jaw crusher. Lapis Lazuli is incredibly hard, making it more challenging to crush than materials like marble or glass, which break down easily by comparison. The crushing process releases a distinct smell reminiscent of burned matches.

Once crushed, the sand is thoroughly washed with water. The cleaned Lapis Lazuli sand is then wet milled in a metal-free environment to avoid contamination. Due to the hardness of the sand, the milling process is lengthy, starting with larger media and progressing to smaller media to achieve particle sizes under 50 microns. This extended milling time necessitates non-contaminating methods to preserve the purity of the pigment. Reflecting on historical methods, such as those described by Cennini, reveals how contamination from tools like bronze mortars might have impacted the final product in the 14th century.

The key to producing smooth, high-quality pigment is reducing the particle size enough to separate blue crystals from colorless contaminants without making them too fine. The desired purplish tone, unique to Lapis Lazuli, emerges during this careful size reduction. Initially, the color of the mixture appears gray rather than blue, with the true color only becoming evident after multiple washes to neutralize the pH and settle the solution. The final product, a fine Lapis Lazuli powder known as fine 303030, is air-dried before the pigment extraction process.

Master Pigments' commitment to traditional methods and meticulous preparation ensures that their Lapis Lazuli pigments capture the rich, historical beauty of this exceptional stone.

Pigment extraction

The Alchemy of Pigment Extraction

The true alchemy begins now. The process is based on a recipe from "The Craftsman's Handbook" by Cennino d'Andrea Cennini, translated by Daniel V. Thompson, Jr. The original Italian text was invaluable, and I extend my gratitude to the 'maestro' for his guidance. After extensive research and numerous trial-and-error attempts, Master Pigments has perfected the extraction of this unique pigment.

Years of searching for the right ingredients and refining the preparation steps culminated in a meticulous procedure. Different grades of pigment are extracted through this process. A plastic dough made of resin and powder remains intact throughout the extraction. There is no disintegration or wrapping in cloth—just oiled hands, dough, and water.

The preparation starts by melting raw beeswax, gum mastic, and pine rosin, then mixing in the prepared pigment. The mixture is kneaded by hand until it forms a uniformly textured dark grayish-blue dough. While still hot and elastic, the dough is divided into three parts and shaped into sticks for easier handling. Each stick is kneaded by hand in hot water through a specific routine, repeated multiple times. The dough locks in impurities while pigment particles settle at the bottom of the container. This is truly a 'hand-made' pigment.

The first routine yields the best grade: a vivid, deep blue that is not dark but hypnotizing. This is the Fra Angelico blue pigment (303001), evoking an uplifting and purifying sensation, as if there is more to see beyond the visible blue spectrum. The second and third routines produce a very high grade of blue known as Lapis Lazuli – Pure Grade 1st pigment (303005). Both Fra Angelico blue and Lapis Lazuli Pure 1st grade require immense patience during the dough preparation and extraction.

From the fourth to the seventh routine, the dough releases beautiful blue particles, resulting in Lapis Lazuli - Ultramarine Ash (303010). This grade is a lovely blue, free of grayish tones but not as vivid as the higher grades, appreciated by painters for its transparency and vibrancy compared to the raw powder.